Edible Oil Refining

Process & Infrastructure

STORAGE TANK CLEANING

Professional Tank Cleaning for Edible Oil Storage Terminals

At Ambaji Imports, we excel in providing comprehensive tank cleaning services for edible oil storage terminals, ensuring adherence to the highest standards of cleanliness and safety. Upon receiving intimation from our Registered Office, we promptly initiate the process by opening the manways and ventilating the tank to ensure it is gas-free and safe for confined space entry. We use an oxygen meter to confirm safe oxygen levels and obtain the necessary confined space entry permits.

SHIPMENT

Efficient Shipping Preparation for Edible Oil Storage Terminals

A. SHIPMENT PREPARATION

At Ambaji Imports, we ensure a seamless shipping preparation process for edible oil storage terminals. Upon receiving shipment intimation from our Registered Office or customer, our Terminal In Charge gathers all necessary details. The Operation In Charge then organizes and supervises the shipment, coordinating with the Customs House Agent (CHA), vessel agent, and port authority to verify customs permissions, supervision, and the bill of lading.

GAUGING

Accurate Gauging for Edible Oil Storage Terminals

At Ambaji Imports, precise gauging of tanks is critical to maintaining the quality and safety of edible oils. Our process begins with selecting the correct dip tape for the specific tank. After opening the gauge hatch, our trained personnel hold the tape handle and release it slowly using the small handle, ensuring the tape touches the side of the hatch as it is lowered to the reference height indicated on the tank roof.

TEMPERATURE MEASUREMENT

Precise Temperature Measurement for Edible Oil Storage Terminals

At Ambaji Imports, we prioritize accurate temperature measurements for optimal storage of edible oils. Utilizing calibrated thermometers fixed within protective cup cases, our process begins by carefully lowering the thermometer cup into the tank until it reaches the centre of the product level. The cup is then kept in this position for a standardized duration of 5 minutes to stabilize the reading.

CALCULATION OF STOCK/ QUANTITY

Precise Stock Calculation for Edible Oil Storage Terminals

At Ambaji Imports, we employ calibrated charts to determine product volume through dip measurements. We calculate the weight of the product in metric tons (MT) using standard density values adjusted for observed temperature. This method ensures accurate stock records maintained in our comprehensive tank stock register. Our commitment to precision allows us to reliably manage and monitor edible oil quantities, providing our clients with transparency and confidence in their storage operations.

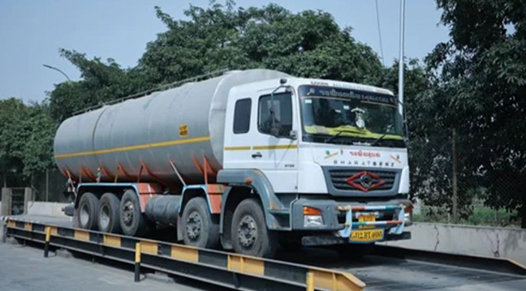

WEIGHMENT OF TANK TRUCKS

TARE WEIGHT - Efficient Tank Truck Weighment at Edible Oil Storage Terminals

Ambaji Imports ensures the precise weighing of tank trucks at our edible oil storage terminals to maintain accuracy and reliability in operations. We begin by preparing the weighbridge platform, ensuring it is clean and free of water before switching it on and verifying zero readings. Any discrepancies are promptly reported to the Terminal In-Charge for resolution with authorized personnel.

OPERATION OF PUMPS

Efficient Operation of Pumps at Edible Oil Storage Terminals

At Ambaji Imports, we ensure the efficient operation of pumps at our edible oil storage terminals to maintain optimal storage conditions. Our process begins with verifying the proper voltage supply of 415V to motor mains and starters across all three phases. We meticulously monitor oil levels in the pumps to ensure consistent performance and reliability.

TANK TRUCK FILLING

Efficient Tank Truck Filling at Edible Oil Storage Terminals

Ambaji Imports excels in the precise and safe filling of tank trucks at our edible oil storage terminals. Our process begins with the Operation In-Charge instructing the Weighbridge In-Charge to commence weighing after clearance by the customer surveyor. Upon authorization, tank trucks are safely guided inside the terminal for product delivery.

Contact us today

Learn more about our customised solutions and how we can help your business grow.